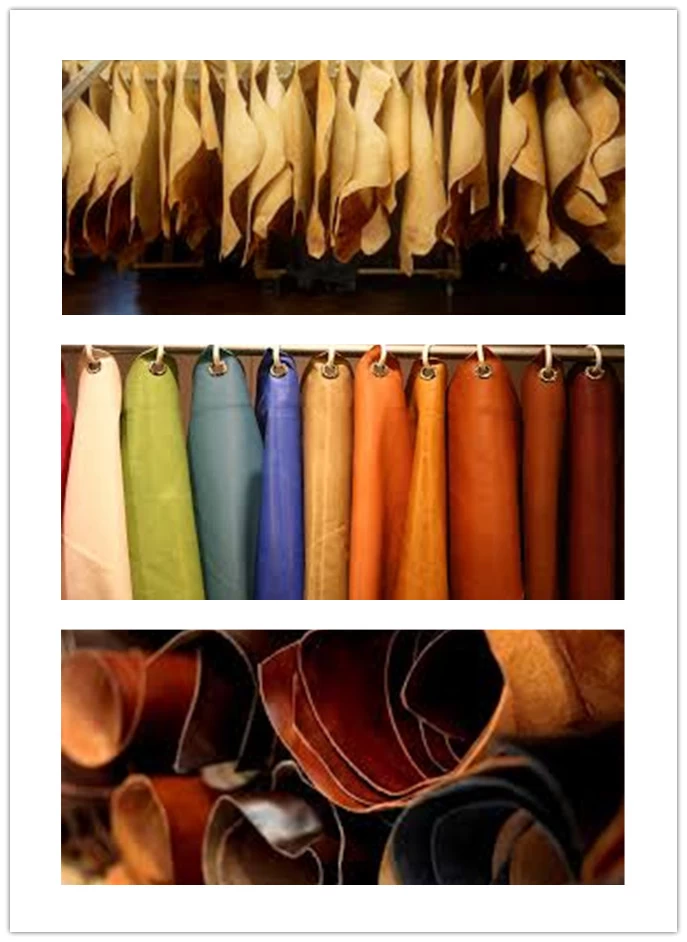

Several tanning processes transform hides and skins into leather

Cara

www.walletamazon.com

2017-04-06 17:29:47

- Chrome-tanned leather, invented in 1858, is tanned using chromium sulfate and other chromium salts. It is more supple and pliable than vegetable-tanned leather and does not discolor or lose shape as drastically in water as vegetable-tanned. It is also known as wet-blue for its color derived from the chromium. More exotic colors are possible when using chrome tanning. The chrome tanning method usually only takes a day to finish, and the ease and agility of this method make it a popular choice. It is reported that chrome-tanned leather adds up to 80% of the global leather supply.

- Vegetable-tanned leather is tanned using tannins and other ingredients found in different vegetable matter, such as tree bark prepared in bark mills, wood, leaves, fruits, and roots. It is supple and brown in color, with the exact shade depending on the mix of chemicals and the color of the skin. It is the only form of leather suitable for use in leather carving or stamping. Vegetable-tanned leather is not stable in water; it tends to discolor, so if left to soak and then dried it shrinks and becomes harder. In hot water, it shrinks drastically and partly congeals—becoming rigid, and eventually brittle. Boiled leather is an example of this, where the leather has been hardened by being immersed in hot water, or in boiled wax or similar substances. Historically, it was occasionally used as armour after hardening, and it has also been used for book binding.

- Aldehyde-tanned leather is tanned using glutaraldehyde or oxazolidine compounds. This is the leather that most tanners refer to as wet-white leather due to its pale cream or white color. It is the main type of "chrome-free" leather, often seen in shoes for infants and automobiles.

- Formaldehyde tanning (being phased out due to danger to workers and sensitivity of many people to formaldehyde) is another aldehyde tanning method. Brain-tanned leathers fall into this category, and are exceptionally water absorbent.

- Brain tanned leathers are made by a labor-intensive process that uses emulsified oils, often those of animal brains such as deer, cattle, and buffaloes. They are known for their exceptional softness and washability.

- Chamois leather also falls into the category of aldehyde tanning, and like brain tanning, produces a porous and highly water-absorbent leather. Chamois leather is made using marine oils (traditionally cod oil) that oxidize easily to produce the aldehydes that tan the leather to color it.

- Rose-tanned leather is a variation of vegetable oil tanning and brain tanning, where pure rose otto replaces the vegetable oil and emulsified oils. Rose-tanned leather tanned leaves a powerful rose fragrance even years from when it is manufactured. It has been called the most valuable leather on earth, but this is mostly due to the high cost of rose otto and its labor-intensive tanning process.

- Synthetic-tanned leather is tanned using aromatic polymers such as the Novolac or Neradol types (syntans, contraction for synthetic tannins). This leather is white in color and was invented when vegetable tannins were in short supply during the Second World War. Melamine and other amino-functional resins fall into this category, as well, and they provide the filling that modern leathers often require. Urea-formaldehyde resins were also used in this tanning method before people realized the hazards that formaldehyde presents to tanners and consumers.

- Alum-tanned leather is transformed using aluminium salts mixed with a variety of binders and protein sources, such as flour and egg yolk. Alum-tanned leather is technically not tanned, as tannic acid is not used, and the resulting material reverts to rawhide if soaked in water long enough to remove the alum salts.

- Rawhide is made by scraping the skin thin, soaking it in lime, and then stretching it while it dries. Like alum-tanning, rawhide is not technically "leather",[citation needed] but is usually lumped in with the other forms.[citation needed] Rawhide is stiffer and more brittle than other forms of leather; it is primarily found in uses such as drum heads and parchment where it does not need to flex significantly; it is also cut up into cords for use in lacing or stitching and for making many varieties of dog chews.